However, when dealing with the coupled mechanical and hydrogen transport problems, a so-called Oriani’s assumption and McNabb and Foster equation are widely used in the models. Similar hydrogen diffusion models coupling with stress were also developed by other researchers to study different problems. Thus, the role of microstructure on hydrogen diffusion is associated with hydrogen trapping in multi-precipitate distributions simultaneously. , the hydrogen-trapping approach is combined with physical modeling of nucleation, growth, and coarsening of second-phase particles within the matrix, and the hydrogen-trap binding enthalpies and mechanical loading conditions are of relevance too and are considered. repeatedly revisited the coupled hydrogen diffusion simulation proposed by Sofronis et al., but they considered the plastic strain rate, the coupled diffusion, and stress-state dependent boundary conditions in the model.

#COMSOL 5.1 CRACK CRACK#

However, the hydrogen concentration is imported as a predefined field and it is not updated during crack propagation, so a fully coupled model was developed to simulate the coupling of thermal stress, mass diffusion, and heat transfer. proposed a weakly coupled approach with three steps to present the couples between hydrogen diffusion and stress-strain analysis in Abaqus. firstly determined the loading speed so that a steady-state hydrogen distribution is achieved and then studied the conjoint effect of hydrogen and stress state on ductile fracture by unit cell model. Considering that sufficient time is needed for the diffusion process to reach a steady state of hydrogen distribution between the trapping sites and the normal interstitial lattice sites.

#COMSOL 5.1 CRACK UPDATE#

developed a fully implicit numerical algorithm to superimpose the hydrogen-induced strain onto the equivalent plastic strain during the stress update process within each iteration on each integration point in the implicit backward Euler algorithm, by which the interactive plastic strain and the hydrogen concentration could be solved simultaneously.

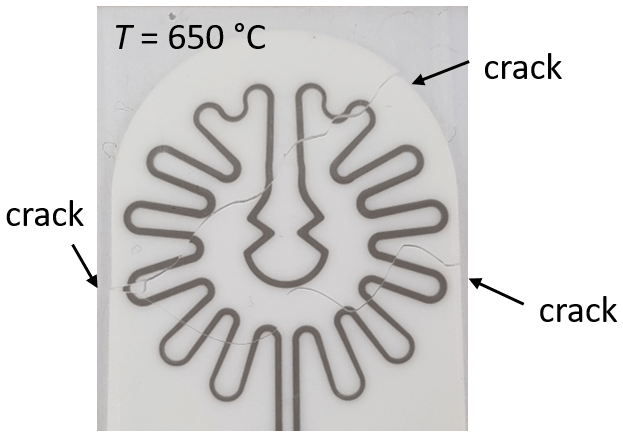

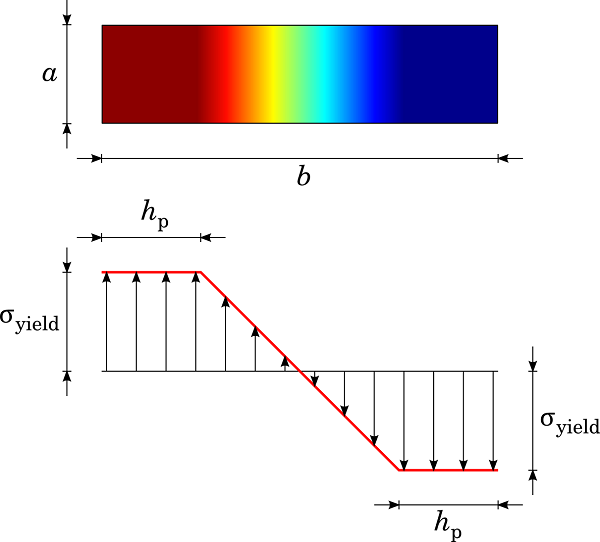

Following Sofronis and Mcmeeking’s work, Cui et al. And then Abramov and coworkers used a model accounting for diffusion and trapping based on McNabb and Foster’s work and Oriani’s extension for local equilibrium between lattice and trap sites. It was found that the hydrogen transport process is strongly influenced by the hydrostatic stress and the plastic strain, so Sofronis and McMeeking carried out coupled diffusion elastic-plastic stress finite element analyses incorporating the effect of hydrostatic stress and trapping. Of all the mechanisms mentioned, it is very important to accurately model the hydrogen transportation process in metals when determining the likelihood of cracking. Several mechanisms have been summarized to reveal the reason for hydrogen embrittlement, including the stress-induced hydride formation and cleavage mechanism, decohesion, and the hydrogen-enhanced localized plasticity mechanism. Although titanium is considered to be immune to corrosion, the hydrogen embrittlement, which manifests as a reduction in mechanical properties of titanium and its alloys, becomes a common phenomenon when they come in contact with a hydrogen-containing environment. Titanium and its alloys are attractive materials for many structural applications in aerospace, industrial, and marine, because of their excellent specific strength, stiffness, and corrosion resistance. The proposed model is expected to solve the hydrogen concentration under stress in more complex structures.

When a plastic zone exists in front of the crack tip, the highest hydrogen concentration at crack surface deviates to the side near the crack tip a hydrogen concentration peak exists at a characterized distance in front of crack tip initially and then diminishes with the diffusion process. When the stress state of the crack tip is elastic, the hydrogen will diffuse from both sides of the crack towards the tip and lead to the highest hydrogen concentration in the crack tip. The results indicate that hydrogen diffusion near the crack is determined by the stress state.

#COMSOL 5.1 CRACK SOFTWARE#

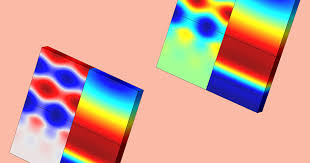

A titanium plate with a central crack was modeled to verify the mechanic-diffusion model, and it is solved by the finite element method in commercial software COMSOL. In this paper, the hydrogen atoms are assumed to reside in interstitial sites and in trapping sites such as dislocations, and a mechanic-diffusion coupled model was proposed to describe the stress effects on the diffusion of hydrogen in titanium. Hydrogen plays a detrimental effect on the degeneration of titanium and its alloys, and it is very important to quantify the hydrogen concentration when estimating the microstructure evaluation of titanium and its alloys in a hydrogen environment.

0 kommentar(er)

0 kommentar(er)